Kuber Motgi

aBOUT me

Originally from India and currently living in the United States as a permanent resident for the past 5 years. Graduated in 2019 from the University of Washington, with a Bachelor of Science Degree in Mechanical Engineering, and experience working on multiple interdisciplinary engineering projects.

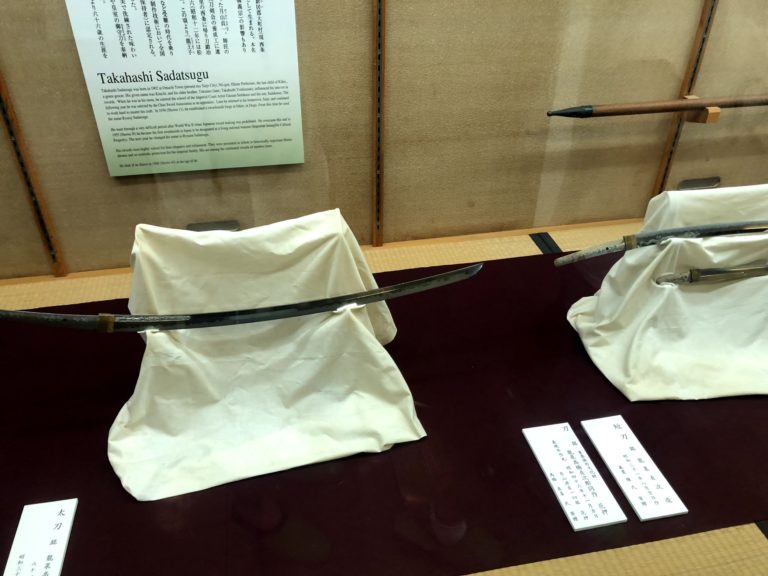

One of the most notable and memorable accomplishments in my engineering career was to build unique stair climbing rovers for UW Bothell’s Hackathon competition. Similarly, I was part of a study abroad program which provided me the ability to adopt social, cultural and educational expertise from a wonderful country like Japan. Apart from that, I have a passion for outdoor wellness and exploring multiple outdoor destinations around the US and the world. In my free time I sing and play guitar, and I’m working towards improving my skills by adapting different genres of music. As a recent engineer graduate, nature enthusiast and adventurer I would like to continue my journey of exploring what the world has to offer, and this website has been created to provide a platform of all my adventures and achievements.

Kuber Motgi has experience Working in the Medical Device industry, and interest to establish a career in the automotive Field

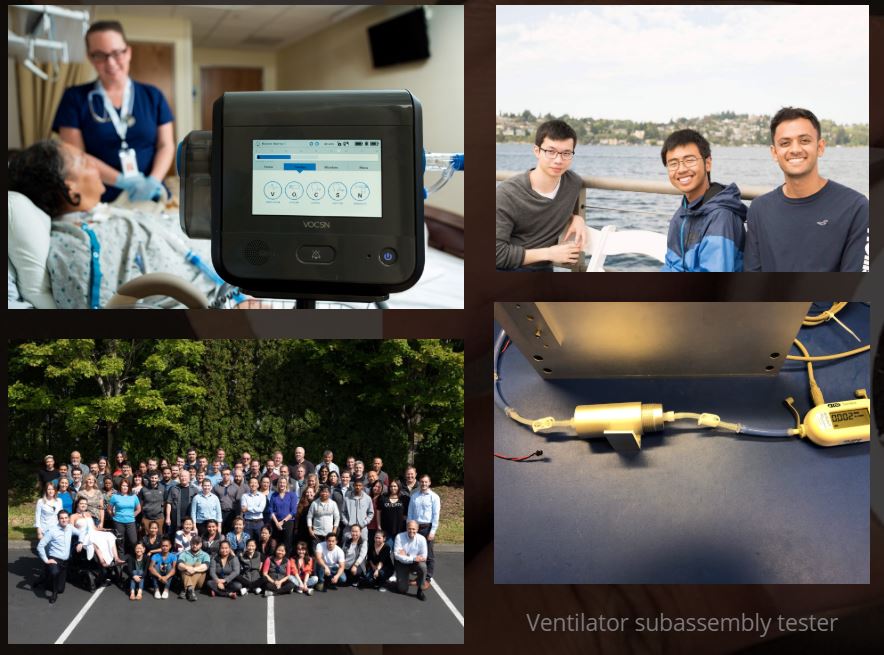

Currently working in Abbott Diabetes Care to improve the production of fully mechanical applicator for a continuous glucose monitoring device(FreeStyle Libre 3) that eliminates the use of finger sticks.

Prior to working at Abbott I had the opportunity to work with Ventec Life Systems, who have recently partnered with General Motors to manufacture lifesaving ventilators for the nation’s fight against COVID-19. As a Mechanical Engineering Intern at Ventec Life Systems, I improved the performance and longevity of the VOCSN units for almost a year. It is an honor being able to work for medical device companies with many smart, passionate and hard working engineers to help prolong or save people’s lives.

It is very rewarding to work in a medical device industry and to use my knowledge to help people fight the toughest of diseases. However, my passion lies in working under large scale automotive manufacturer and to build EVs that can potentially help reduce our carbon footprint, eliminate human driving errors, boost machine efficiency and to preserve the valuable resources that earth has presented us. I’m constantly looking to grow, learn, take on challenges and my commitment to engineering will provide the motivation I need to achieve my dreams.

sKILLS

SOlidWorks

2+ year SolidWorks experience ranging from design projects in classroom, Hackathon competitions, industrial application to improve the functionality and/or troubleshoot components of the ventilators.

Manufacturing

1+ year experience performing Geometric Dimensioning and Tolerancing (GD&T) , consulting senior engineers and machinists to customize parts using CNC Lathe, Drill Press and Mill.

Analyzed the need for parts/test fixture improvements with quality and manufacturing engineers to execute changes to the pre-existing setup.

MEchatronics

Experience programming Arduino processors and Raspberry Pi for a hackathon competition. Worked with PWM modules, sensors and RGB lights, to control the traps and other essential components for the rover robots.

Additive Manufacturing

Experience designing, modifying and 3D printing parts for various purposes like – electrical enclosures for autonomous trike, complex parts for the rover robot and design project for SolidWorks class

Programming - Java, C#, C, Python

Used Python programming language to accomplish wireless motor controls for the rover using RPi, C programming language in an Arduino to control traps and obstacles for the rover robot . Experience using Java and C# for classroom projects, assignments and

LabView

Familiar with LabView for mechatronics application and classroom projects. Utilized LabView to control many testing/troubleshooting application for the VOCSN Ventilators sub-assembly.

Inventor

Self-Trained Knowledge of Inventor for Interviews

MATLAB

Experience programming in MATLAB for different projects in the classroom to simplify complex engineering problems

Experience

MECHANICAL ENGINEERING – Abbott Diabetes CARE

- Pitched unique design ideas for Continuous Glucose Monitoring(CGM) device

- Designing next generation CGM and editing functionable assemblies as per design specifications within deadlines

- Redesigned/Rescaled specific features of the Continuous Glucose Monitoring (CGM) component using SolidWorks

- Performed Tolerance analysis to identify feasible clearance between multiple components inside the applicator

- Calculated air leaks using the ideal gas equation and compared the values by creating a Solid body that mimics the inside volume of the CGM applicator using SolidWorks

- Evaluated the delta velocity and displacement graphs using the Keyence High Speed Camera to assess performance of modified components during dynamic application

- Artificially modified application force and performed Instron force testing to verify if the proposed change is a feasible option

Mechanical Engineering Internship/Co-oP- Ventec Life Systems

50 employees

- Performed SolidWorks 2D/3D CAD modelling to design and prototype an R&D test stand, for the oxygen concentrator using fasteners, gaskets, metal and plastic parts

- Referenced Apple O-ring guide and Starrett guide, while applying standard engineering principles and material selection to build a test stand with internal threading and insulation properties

- Performed failure analysis to identify oxygen concentrator’s vulnerability to water contamination, ran cycle testing in various conditions of the thermal chamber and tested the overall failure of the sub-assembly

- Collected data from the production line and evaluate manufacturing processes, carried out low/high pressure leak tests on compressors, rotary valves and regulators; to identify faults in the sub-assemblies

- Collaborated with senior mechanical, electrical and software engineers to troubleshoot/analyze components, support ECO release and automate R&D/Inspection test stands with relays & solenoid to control voltage at 60 cycles/min

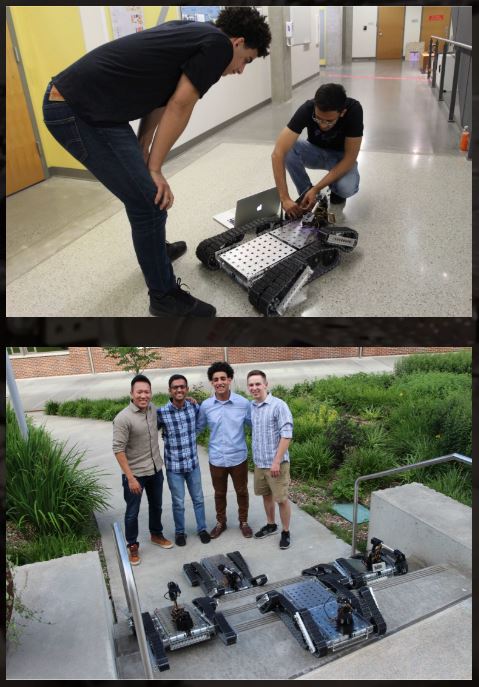

Rover successfully climbing stairs

Project Lead – Rover Robotics – Capstone Project

16 Engineers (T-Mobile)

University of Washington School of Mechanical Engineering

- Prototyped, programmed (RPi) and built a unique stair climbing rover while overseeing 10-15 engineers, for a capstone project turned hacking competition with interdisciplinary engineering students

- Firsthand experience designing a unique 22 x16 inch rover, using plastic/metal parts on SolidWorks

- Programmed Raspberry Pi using Python to control H-Bridges and IRs/photovoltaic sensors for the rover wirelessly, used buck to buck modules to bring down voltage from 12 V to 6 V using a motorcycle battery to power all electronics

- Proactively experimented with worm gear, idler wheels and torque motors to come up with optimal mechanism

- Modified metal/plastic parts in the machine shop using Lathe, Drill Press and Bench Grinder

- Performed FEA, Stress and Dynamic analysis to test integrity and toughness of the rover robot’s assembly

- Created BOMs, documented design, testing and assembly instruction to help fellow other engineers reference work

Undergraduate Researcher – Elcano Project Self Driving Tricycle 8 Engineers

University of Washington School of STEM

- Redesigned the layout of the Arduino board processors to aid with efficiency and space management on the tricycle,

by saving 8-10% space on the tricycle - Executed serial wiring of the Arduino to other processors, RC receivers and GPS shields

- Performed 3D printing and designing( mounts, sonar casing)

- Provided Routine Maintenance to actuators, brakes and rotors for testing

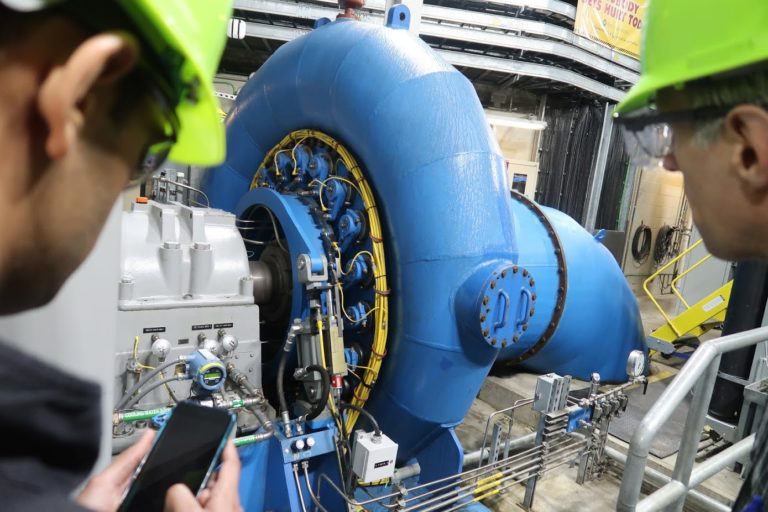

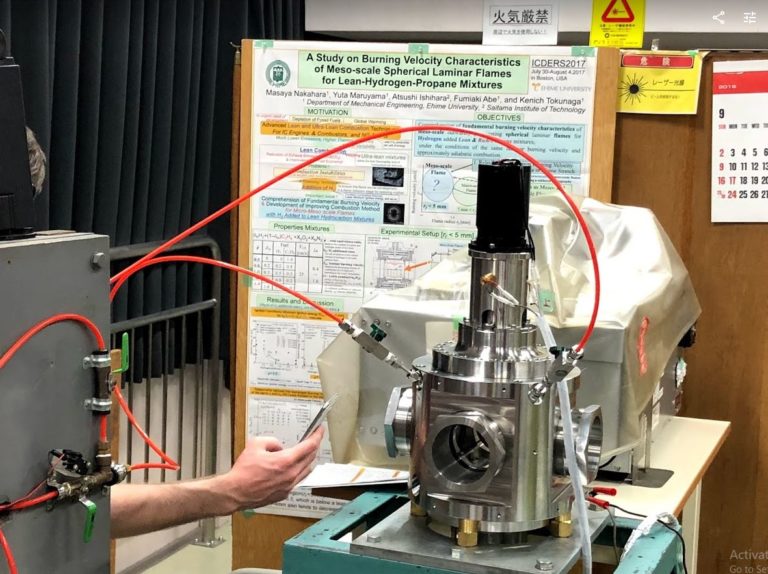

Study Abroad- Sustainable Energy in Japan

Ehime University of Mechanical Engineering- Matsuyama, Japan

- Shown apt communication skills by corresponding with Japanese energy professionals, to discuss the energy policies and to further inspect the potential of clean energy for future use.

- Examined the potential of nuclear energy and communicated with Japanese representatives with regard to Nuclear energy policies in Japan and its impact on the country’s economy.

- Demonstrated commercial skills by reasoning with energy officials on Japan’s inclination towards hydrogen fuel/fuel cell and discussed their strategies to produce and/or import hydrogen fuel

Independent Researcher- Geothermal Heating and Cooling System

University of Washington – Sustainability Office at Physical Plant

- Collaborated with the Sustainability Coordinator and presented monthly research progress reports to convey progress

- Consulted professional about the capabilities of the systems and argued about other renewable energy systems to understand the pros and cons

- Promoted the functionality of the system to the University of Washington students

- Presented research at the UW research symposium

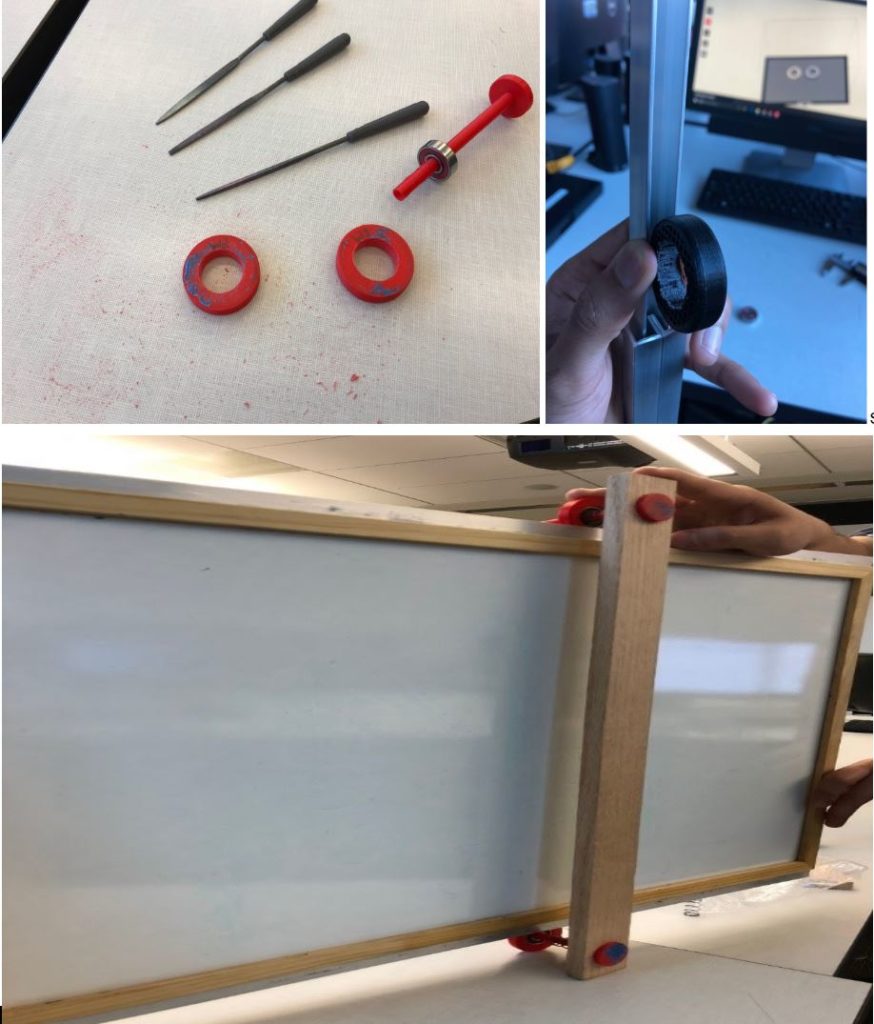

3D Modelling Design Project, One Swipe Whiteboard

University of Washington Bothell

- Implemented project models with rails, connecting rods, wheels and brackets in SolidWorks

- Enforced Stress Analysis, used SolidWorks Simulation and FEA to analyse critical points of the design

- Carried out 3D printing of wheels and shafts to fit the exact dimensions of the bearings and rails

- Achieved desired dimensions by using workshop tools and equipment

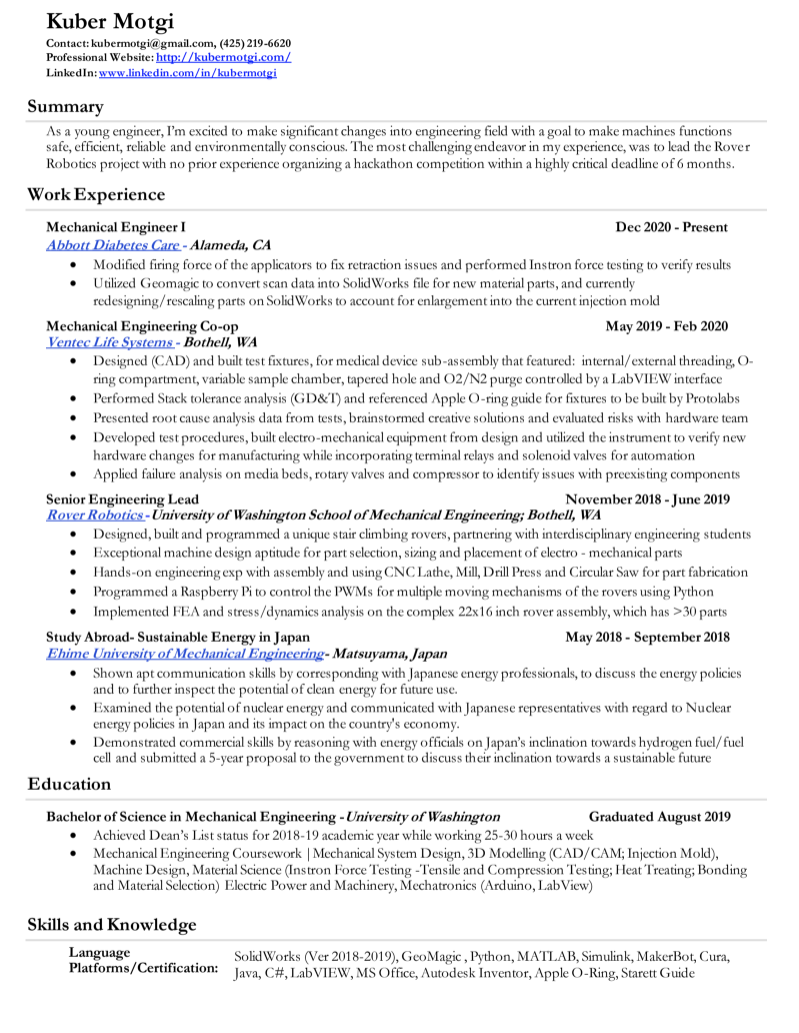

Resume

My Study Abroad in Japan

Contact Me

- Email: kubermotgi@gmail.com

- Phone:+4252196620

-

Location: Oakland,CA